Hard water problems and low water flow - What is causing this?

Hard water problems and low water flow

Q:

Hello. We recently looked at purchasing your AquaTek Pro water softener but, decide to purchase the more expensive Culligan Gold series water softener because, we thought, it would be a better system. With the new Culligan water softener, the water flow in our house has dropped dramatically and often the water feels hard. Can you tell me why that is happening and what we can do to fix it? Thanks! Becky

A:

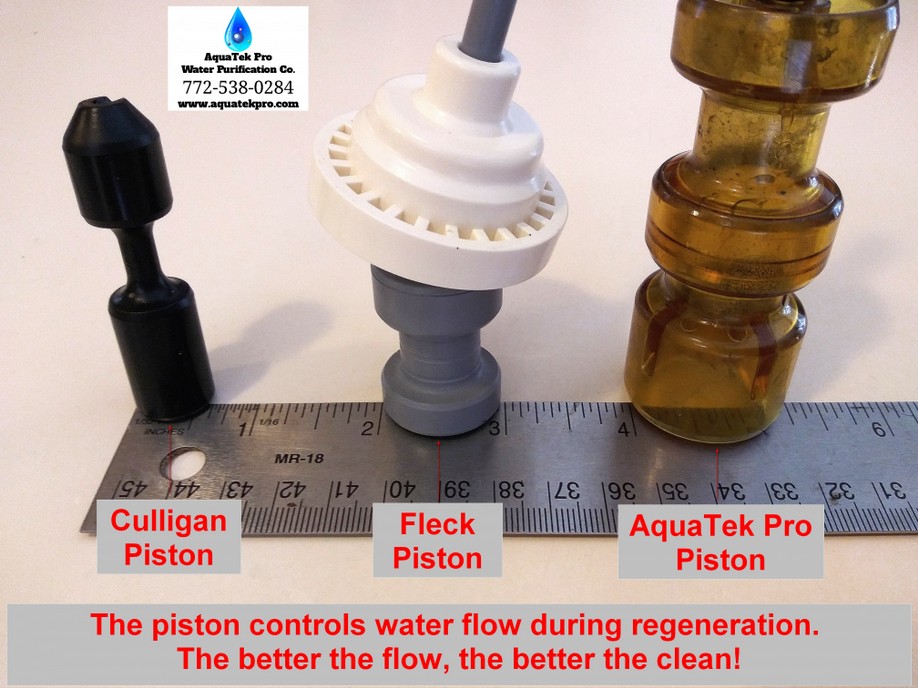

Hello Becky! Sorry to hear you are having issues and hopefully the following pictures will help shed some light on what is going on. There are pistons (below) that, control water flow through a water softener control valve. In the photo below are three pistons; one is from a Culligan Gold series control valve, one is from a Fleck 5600 control valve and one is from an AquaTek Pro 1000 control valve. The smallest piston is the Culligan piston at 5/8″. The Fleck piston is a little bigger at almost one inch and the piston of the AquaTek pro control valve is the biggest at 1 1/4″.

Water softener control valve pistons by Culligan, Fleck and AquaTek Pro.

The pistons are located in a chamber of seals and spacers that allow water to pass in the directions it needs to go. Not only the size of the piston effects flow but, also the size of all the other passages within the valve. Below, is a photo of the pistons mounted in their respective seals and spacers. Hopefully things are beginning to become clear by looking at the photos.

5/8″ Culligan Gold series best flow rate: 10.6 GPM

11/16″ Fleck 5600 best flow rate: 20 GPM

1 1/4″ AquaTek Pro 1000 best flow rate: 27 GPM

The first step to every water softener when it goes into regeneration, is the backwash cycle. This means, the water flowing through the water softener reverses flow. Instead of pushing down on the softening resin contained in the media tank, the control valve sits on; it is flowing upward. This upward flow of water should be strong enough to lift the softening resin up, to release particles which, may have been caught during normal (service) operation.

unit_operation_1

unit_operation_2

When the water flowing through the water softener is able to lift the softener resin, you will get a good clean during the regeneration process. If the flow is insufficient, the regeneration process is hindered and over time problems can occur. High iron content can bind the resin and hinder the rising of the resin during backwash. High hardness content, with low flow, can result in some of the hardness remaining stuck to the resin when, it should have been released by the salt brine and flushed out of the water softener.

Lifting the softening resin during backwash is important because, over time, water can tunnel through a resin bed causing a loss of softening capacity. A good backwash that will lift the resin, disrupts tunneling so, water can travel through all of the resin bed evenly.

However, there are many other factors that can cause a loss of water flow. The size of piping used, the number of elbows used, malfunctioning parts, clogged orifices and improper system pressure settings, can all effect water flow to the structure they are attached to. We really can’t pin point the exact cause unless, we come to your house and do a system evaluation. If you would like for us to come out and have a look, call 772-538-0284 and set an appointment.

If we find you need parts for your Culligan water softener, you will have to go back to Culligan because, the are proprietary machines and you must buy the parts from them. We can service your water softener for you if, you obtain the parts needed, from them.